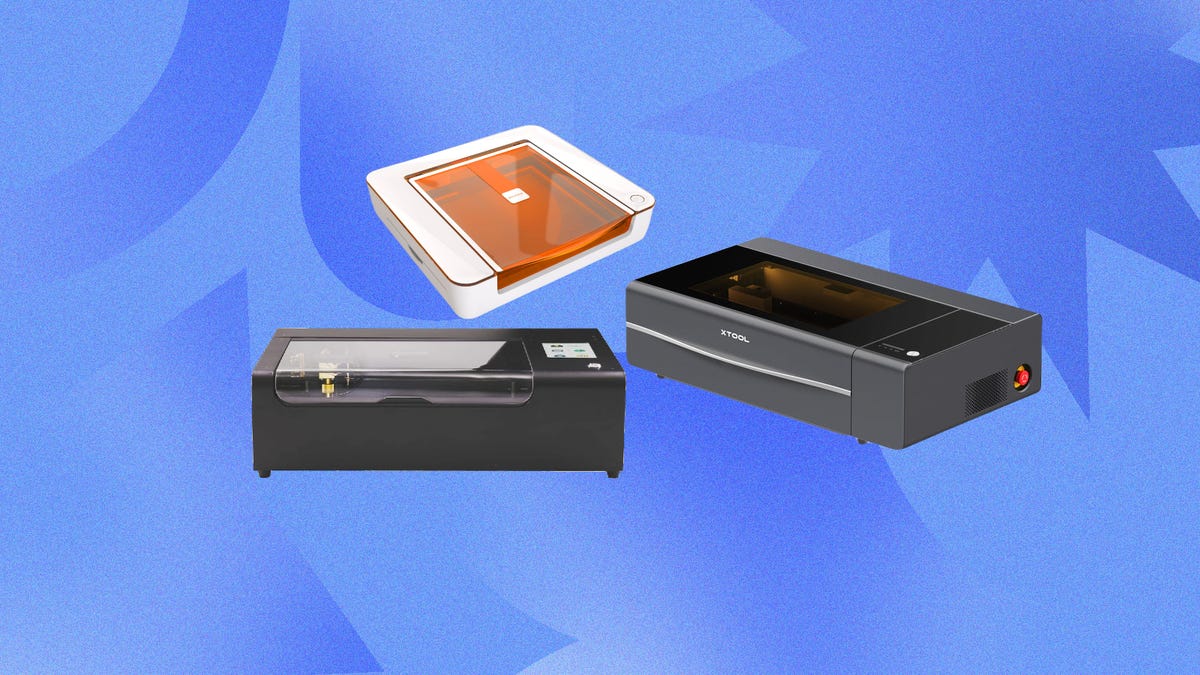

Best in-office laser cutter

Glowforge Aura

View details

With more Americans than identifying as makers, we are seeing new products arrive to scratch that itch every day. Machines like 3D printers, vinyl cutters and laser cutters are now available at prices to fit just about any pocketbook. They allow people to bring their creations to life in new and interesting ways. You can even turn a profit on stores like Etsy and Shopify if you have the right materials and machines.

I’ve used laser cutters for about five years to create various projects, from small dog tags to etching a 7-foot workbench with elven runes. Each cutter I use has a host of different pros and cons, so along with my CNET colleague Russell Holly, I’ve developed testing criteria to assess the best laser cutters.

You may notice that there are no open laser cutters on this list. After testing several I find them to be too dangerous for the average user. They could be good for commercial spaces, but having an open laser in a garage is just too dangerous for me to recommend.

What’s the best laser cutter?

The xTool P2 is our top pick for the best laser cutter. It isn’t the cheapest laser cutter around, but with a host of amazing accessories, fantastic software and a cutting size and speed that are hard to ignore, it takes the crown from the Glowforge Pro, but just barely. It’s huge, so make sure you have room in your workshop to house it.

Best laser cutters of 2024

The xTool P2 is the complete package for fast, powerful laser cutting at home or in a small workshop. With a full suite of accessories that let you cut 3-meter-long materials and round tumblers and glasses, the P2 can cut or etch any material you could hope for, including glass and transparent acrylic.

The software is excellent and can help you design your creations to better fit your cutting needs. The camera works well to help you align your materials, but be careful when working near the edge of the camera limits, because the fisheye distorts a little. This bundle comes with some materials to get you started and a fire safety system to give you peace of mind.

Read our xTool P2 review.

The Glowforge Aura is the company’s first consumer laser cutter aimed at the entry-level market. It’s smaller than the other models, with a less powerful laser, but it works amazingly well on smaller projects. We’ve made beautiful carvings, etchings and other laser-cut projects on the aura, and all of them have been excellent.

Read more: Hands-on with the Glowforge Aura

It’s been a while since I’ve had as much fun with a maker tool as I have had with the xTool F1. It’s lightweight and very easy to transport if you go to many trade shows, conferences or farmer’s markets and, with the accessories in this bundle, you can etch batches of products as easily as one. The software is excellent too, making it easy to line up projects or trace out new projects from a photo.

I recently took the F1 to a STEM fair for primary school kids, and it was extremely popular as it whizzed around cutting out the school logo onto metal business cards. While the price is pretty high for a cutting area this small, you could easily make your money back with just a little work at a farmer’s market stall or two. It’s well worth the investment.

The Beamo is the smallest of Flux’s impressive lineup of CO2 laser cutters, but don’t let the small size fool you. The 30-watt laser, while weaker than some on this list, is still powerful enough to etch glass, although you may need the additional diode laser to etch onto the steel. It will happily cut through wood, leather and acrylic.

The Beamo also comes with a handy touchscreen on the device, making it much easier to control from your workshop without a computer plugged into it directly. Flux even has an app that’ll let you control the Beamo directly from your phone.

The WeCreat is a fun little box that can etch and cut several materials. It isn’t going to carve through thick wood or steel, but it makes fun projects for family fun time. I think it’s perfect for schools, especially with its exhaust filter, as the enclosure and air assist make it safe for classrooms and stop little fingers from getting burnt. I created several projects for my kid’s kindergarten class, and the teachers all loved it.

While the software isn’t quite as good as Xtool or Glowforge, the camera is accurate and lets you mark where your material is well. It even has testing squares, so you can try out any material and see what power level you need. That’s something all laser cutters should have.

Diode lasers are often low-powered, with no enclosure to keep you safe. The S1 solves both those problems by having a 40-watt laser that can cut through 18mm of wood in a single, albeit slow, pass. It also has a fantastic enclosure with a green lid to filter the laser’s light and an active exhaust to blow away any smoke. The basic kit has air assist — something all lasers should have — and a honeycomb cutting surface to help reduce scorching on the underside of your material.

The S1 doesn’t have a camera — I think it should — so everything is handled very manually. But that’s true for most diode lasers.

Glowforge has made it clear its mission from the start has been to ensure anyone can use what it calls “laser printers,” and the Glowforge Pro is a shining example. A fisheye camera gives you a view of the cutting surface from a web app, which lets you effortlessly click and drag the things you want to engrave or cut. And if you pay for the extra filtration system, you can use this laser anywhere. Of all the systems tested here, Glowforge’s focus on ease of use is a world apart.

With that ease of use comes some limitations you won’t find elsewhere. Many features that make the Glowforge Pro great are available only if you pay a monthly subscription. If you’re not using the Glowforge-made Proofgrade, the process of identifying the correct settings for engraving or cutting becomes quite manual. Additionally, the fisheye lens that Glowforge uses can occasionally cause accuracy issues when you’re cutting or engraving on small, perfectly centered surfaces.

You’ve got questions and we’ve got answers. We hope!

Testing laser cutters is a mix of objective and subjective measures. We spend time measuring speed and accuracy as well as usability and the overall look of the finished product. These tests are done in our labs and workshops over a month to ensure the lasers can endure proper use.

Laser cutter specifications

How do these laser cutters match up

| Xtool P2 | Glowforge Aura | Xtool S1 | Fluxx Beamo | Glowforge Pro | XTool F1 | |

| Laser power | 55 watts | 6w | 40w | 40w | 45W | 10W |

| Laser type | CO² | Diode | Diode | CO2 | CO2 | Diode/IR |

| Work area | 26 x 14 inches | 12 x 12 inches | 498 x 319mm | 24 x 17.5 inches | 660 x 355 | 115 x 115 |

| LED display | No | No | No | Yes | NO | No |

| Enclosed | Yes | Yes | Yes | Yes | Yes | Partial |

| Precision | 0.01mm | N/A | 0.01mm | N/A | 0.025 | 0.02 |

| Max speed | 600mm/s | Unknown | 600mm/s | 300mm/s | Unknown | 4000mm/s |

| Max material thickness | 20mm | 5mm | 18mm | 5mm | 13mm | 5mm |

Speed is tested with a good old-fashioned stopwatch. I created a simple CNET logo design that can be cut on multiple materials. We time how long it takes to complete the cut. We use 3mm basswood, 3mm black acrylic and 3.5mm cardboard for our testing materials, to give us a good overall view. We then compare the speed with the software to see how accurately it calculates the cutting speeds.

The engraving is done with an image of my beautiful dog Indiana Bones. I imported that image into the workspace and used 3mm basswood for the material. I use the standard engraving settings from each machine to engrave Indy onto the wood. My CNET colleague Russell Holly and I then examine the etching for image quality. We’re looking at contrast, the level of detail captured, and how grainy the image is, as well as considering our opinion on the overall quality.

Indiana is the perfect test subject for laser engraving.

For laser cutters with cameras, I created an accuracy test. I designed a file with 10mm and 5mm increments. The file is printed on standard paper and imported into the laser cutter software. From there, we use the laser cutter camera to align the physical marks to the digital and set the laser to cut. Once the laser is finished, we measure the offset using a micrometer to see how accurately the camera represents the paper image. This is especially helpful for laser cutters with fisheye lenses.

Show more