In the dynamic and ever-evolving field of construction, where innovation meets the imperatives of structural integrity, micropiles have emerged as versatile and efficient foundation solutions. Whether embarking on a residential endeavor, a commercial venture, or navigating challenging soil conditions, a profound understanding of micropile installation is not just advantageous but crucial.

Micropiles, often interchangeably known as minipiles or pin piles, represent a class of slender yet high-capacity piles. These structural elements find their niche in supporting buildings and structures where traditional foundation methods face constraints. Comprising components such as steel casing, threaded bars, and grout, micropiles create a resilient foundation system designed to navigate varying loads and ground conditions with finesse. Installation can be done with equipment rentals or purchased equipment from intechanchoring.com.

Types of Micropiles

To make informed decisions for your building project, a nuanced understanding of micropile types is imperative. Consider the following variations.

- Steel-Cased Micropiles: This type incorporates a steel casing that is drilled into the ground. The casing provides structural integrity during the drilling process. Grout is subsequently injected through the casing, forming a robust foundation.

- Uncased or Open-Hole Micropiles: These are drilled without the use of a casing. The grout is directly injected into the hole, establishing a bond with the surrounding soil. These are ideal for projects characterized by favorable soil conditions.

- Grouted Bar Micropiles: This type features a high-strength steel bar enveloped by grout. The bar is drilled into the ground, and grout is injected under pressure. This type offers significant load-bearing capacity.

- Helical Micropiles: These incorporate helical plates on the steel shaft, enabling screwing into the ground. They are well-suited for applications dealing with unstable soil conditions and provide excellent lateral stability.

Planning Micropile Installation

Meticulous planning serves as the bedrock for a successful micropile installation. Navigate through these essential planning steps.

- Site Assessment: Undertake a thorough site assessment to comprehend soil conditions, groundwater levels, and potential obstructions. Evaluate the structural requirements of the building to determine the most suitable micropile type.

- Engineering Analysis: Engage structural and geotechnical engineers to conduct a detailed analysis. Determine load-bearing requirements and design specifications tailored to the specific needs of the micropiles.

- Permitting and Regulatory Compliance: Obtain the necessary permits and ensure adherence to local regulations. Collaborate closely with local authorities to meet environmental and safety standards.

Micropile Installation Process

Embarking on the actual installation process involves a sequence of crucial steps.

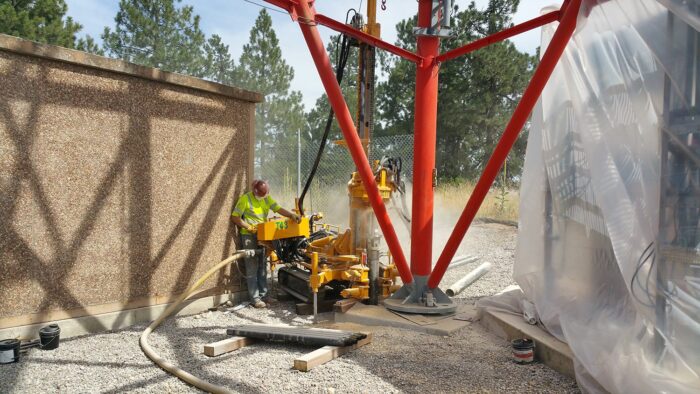

- Drilling: Employ specialized drilling equipment to create holes for the micropiles. Adjust drilling methods based on soil conditions and project-specific requirements.

- Inserting Steel Casing (if applicable): Insert steel casing during drilling to provide additional structural support. The casing prevents collapse, maintaining the integrity of the drilled hole.

- Grout Injection: Inject high-strength grout into the hole, displacing any water or air present. Ensure the formation of a continuous grout column for optimal load-bearing capacity.

- Inserting Reinforcing Bar: Introduce the reinforcing bar into the grout-filled hole. Ensure proper alignment and embedding for structural integrity.

- Post-Installation Testing: Conduct load tests to verify the integrity and load-bearing capacity of the installed micropiles. Adjust installation parameters as necessary based on test results.

Challenges and Mitigations

Micropile installation, like any construction process, may encounter challenges. Effective mitigation strategies include the following.

- Geotechnical Investigations: Conduct thorough soil investigations prior to installation. Implement appropriate drilling techniques based on identified soil conditions.

- Monitoring and Quality Control: Implement real-time monitoring during installation to detect deviations. Enforce strict quality control measures to guarantee the integrity of the micropiles.

- Adaptive Planning: Develop contingency plans to address unforeseen challenges. Be prepared to adjust installation methods based on real-time feedback.

Advantages of Micropiles

Understanding the multifaceted advantages of micropiles is integral to making informed decisions for your building project.

- Versatility: Micropiles are adaptable to various soil conditions and can be installed in confined spaces.

- High Load Capacity: Despite their relatively small diameter, micropiles offer exceptional load-bearing capacity.

- Minimized Vibration: Ideal for projects in urban environments due to their ability to minimize vibration during installation.

- Reduced Environmental Impact: Micropiles generate less spoil and require smaller equipment, reducing their environmental impact.

- Rapid Installation: Micropiles can be installed swiftly, expediting project timelines.

Post-Installation Considerations

Beyond installation, ongoing considerations are crucial for the longevity of micropiles.

- Monitoring and Maintenance: Implement a comprehensive monitoring program to track the performance of micropiles over time. Schedule routine maintenance to address any signs of deterioration or settling.

- Documentation: Maintain meticulous documentation of the micropile installation process, including engineering reports, test results, and as-built drawings.

Future-Proofing Your Foundation

As we look to the future of construction and foundation engineering, micropiles emerge not only as a current solution but as a forward-thinking one. The adaptability of micropiles to varying soil conditions positions them as a reliable choice in an era where urbanization and environmental consciousness are paramount. The reduced environmental impact and minimized vibration during installation align with the global push for sustainable construction practices.

Moreover, ongoing advancements in material sciences and engineering methodologies may further enhance the capabilities of micropiles. Researchers are exploring composite materials for casings and bars, aiming to improve durability and load-bearing capacity. The integration of smart technologies for real-time monitoring could revolutionize the way we assess the health and performance of micropiles, allowing for predictive maintenance and potentially extending their lifespan.

Mastering the art of micropile installation is foundational to the success of your building project. From the initial site assessment to post-installation considerations, each step demands meticulous planning and execution. By understanding the various types of micropiles, addressing potential challenges, and recognizing the advantages they offer, you can ensure a robust foundation that aligns with the specific requirements of your project.

The key to successful micropile installation lies in collaboration with experienced engineers, adherence to industry best practices, and a commitment to ongoing monitoring and maintenance. As you embark on your building journey, consider micropiles not just as a reliable and efficient foundation solution but as a forward-looking choice that harmonizes with the evolving landscape of construction. Providing a solid groundwork for the structures of tomorrow, micropiles stand as a testament to the fusion of innovation and practicality in the ever-expanding realm of construction engineering.